On the evening of May 19, U.S. oil futures rose 8%! The positive news about the vaccine detonated the market, and European and American stock markets soared! The recent good news in the market has continued, which has led to the improvement of the entire gray fabric market. Domestic trade market orders increased, especially market orders began to become popular, and gray fabrics of some specifications were sold briskly.

01

Looming machine operating rate increases, manufacturers Confidence restored

Affected by the improvement in orders, the inventory of gray cloth markets in Jiangsu and Zhejiang has declined. According to data monitoring from China Silk City Network, the current inventory of gray cloth weaving in Shengze is about 41 days, which is lower than It dropped for 3 days at the end of April. The operating rate of weaving manufacturers has also increased. According to data monitoring from China Silk City Network, the current operating rate of water-jet and air-jet looms in Shengze is 75%, and manufacturers are more active in production than in the previous period.

Itcanalsobeseenfromthesedatathatthemarkethasindeedrecoveredtoacertainextent.Inthiserawhereconfidenceismorevaluablethangold,therecoveryofthemarketisnotonlyanincreaseinorders,butalsoarecoveryoftheconfidenceofweavingmanufacturers.ThepersoninchargeofalocalweavingcompanyinShengzetoldtheeditor:”Ourcompanymainlyproducesimitationsilk.Themarkethasimprovedrecentlyandtherearemoreorders.Theoriginaloperatingratewasonly60%,butnowthefactory’soperatingrateis80%.CurrentproductionandsalesWecanmakeaflatsale,mainlyordergoods.”

Fujian, another large gray fabric production base, has also had a high recent start-up rate . It is understood that the person in charge of a manufacturer with 2,000 looms in Fujian said: “The impact of nylon fine-denier products is not very big, almost the same as last year, so the machines are now running at full speed. And in the second half of the year, nylon spinning will be The main force will basically not reduce production and produce normally.

02

The recovery of orders is not strong. There are still manufacturers that have reduced production by 1/3

The operating rates in various regions vary, but overall they are optimistic. However, most manufacturers said that although the market in 2019 was not satisfactory, compared with this year , at this time last year, the machines were fully open and production was not reduced. It can be seen that orders have improved now, but they still have not returned to normal. Manufacturers still need to be cautious about the market outlook.

For example, peripheral areas with very large production capacity, such as Hubei, Henan, Anhui and other places, because there The scale of manufacturers is generally large, so it is reasonable to reduce production. The editor learned that most of the weaving manufacturers in Hubei have reduced production. According to a boss with a weaving factory in Hubei: “After May Day, Hubei Most manufacturers basically stop 1/3 of the machines and start 2/3. Although the market is improving, the best sellers are SPH matte and broken cards. I mainly produce composite silk chiffon, so the impact is not great, and I still have 2 months of inventory. Therefore, there are production reduction operations in Hubei. ”

03

Inventories are high and overcapacity is still a big problem

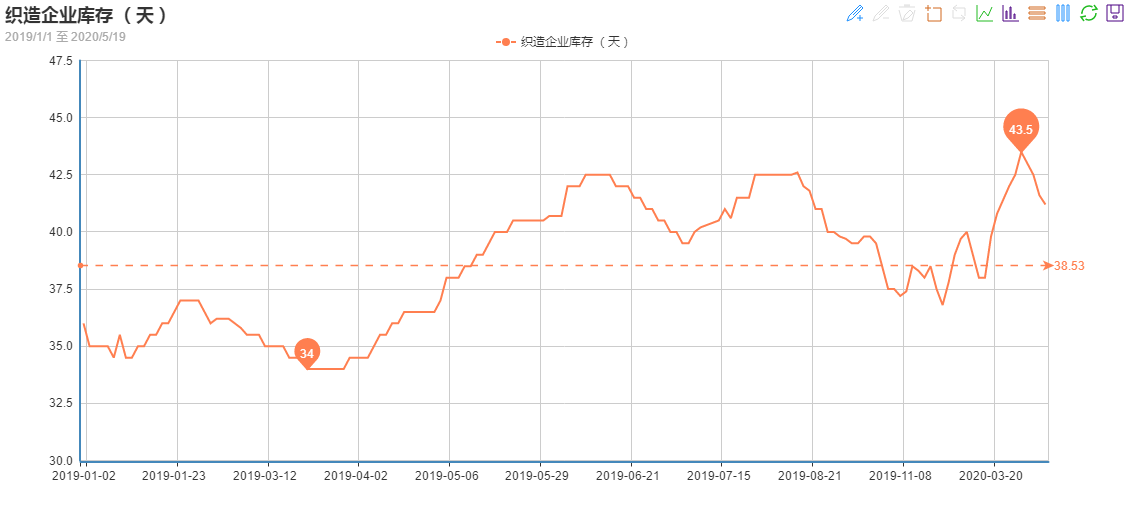

On the one hand, the production capacity in peripheral areas has always been an important factor that cannot be ignored. Under this year’s downturn, it is inevitable that the inventory of gray fabrics will be high. Although the editor has mentioned at the beginning that the inventory of gray fabrics has increased slightly recently. has declined, but compared with the same period in 2019, which was recognized as a sluggish market, it is still 2-3 days higher. Therefore, overcapacity is still a major problem plaguing the gray fabric market.

04

Bounce The market momentum is insufficient and foreign trade orders are recovering slowly

On the other hand, domestic clothing demand has begun to rebound to a certain extent, which is reasonable. Although many countries abroad have lifted the lockdown and resumed work , but downstream foreign trade companies have not received foreign orders, and the recovery of the foreign trade market has been very slow, which has also continued to cause certain obstacles to the overall recovery of the textile market. This wave of market trends may not have enough momentum in the future. Overseas epidemics are still breaking out, and clothing Although it is an urgent need, it is not as good as food and other daily necessities, and clothing consumption will not recover too quickly, so this rebound is not optimistic.

Summary

Even if the market falls back in the later period, it is reasonable. After all, June is the traditional off-season. Now we only need to catch the tail of “Red May” and wait for the peak season in the second half of the year, which is the biggest comfort at present.

</p