Wet forming technology originated from the paper industry. In paper production, fibers are suspended in an aqueous solution. The water flows out from the flat mesh while the fiber material remains on the mesh to form a uniform sheet, which is then bonded, dried, finished and wound. Imported wet-laid polyester non-woven fabric is one of them derivative products.

Wet-laid non-woven fabrics have fast web forming speed, short process flow, high labor productivity and low cost. Its labor productivity is 10-20 times that of the dry method, and the production cost is only 60-70% of that of the dry method. It has strong market competitiveness and good economic benefits. At present, the output of wet-laid non-woven fabrics in developed countries accounts for more than 30% of the total output of non-woven fabrics, and is still growing.

Imported wet-laid polyester non-woven fabricFast web forming speed, short process flow, high labor productivity and low cost. Its labor productivity is 10-20 times that of the dry method, and the production cost is only 60-70% of that of the dry method. It has strong market competitiveness and good economic benefits. At present, the output of wet-laid non-woven fabrics in developed countries accounts for more than 30% of the total output of non-woven fabrics, and is still growing. The output of wet-laid non-woven fabrics in my country is relatively low. According to preliminary statistics, it accounts for less than 5% of the total output of non-woven fabrics. Compared with developed countries, it has a larger potential market.

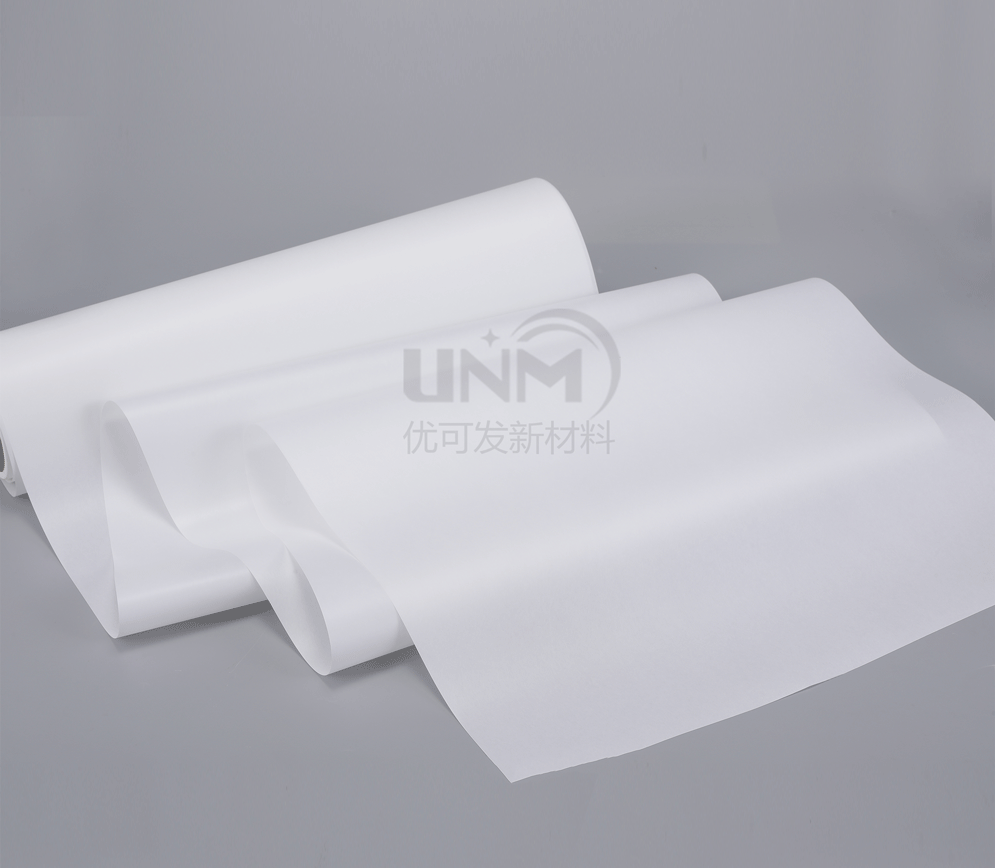

For saleImported wet-laid polyester non-woven fabric can be widely used in air filtration, packaging materials, medical tape, cable wrapping, biofilm and other fields. We have a complete pre-sales, sales and after-sales service system. Interested parties can enter the store to consult us.

</p