PTFE sterile filtration breathable membrane is a material with a microporous structure. It is made of polytetrafluoroethylene (PTFE), which allows Gas penetrates and prevents the penetration of liquids and microorganisms. It is widely used in medicine, food, semiconductor and other fields to ensure product quality and reliability.

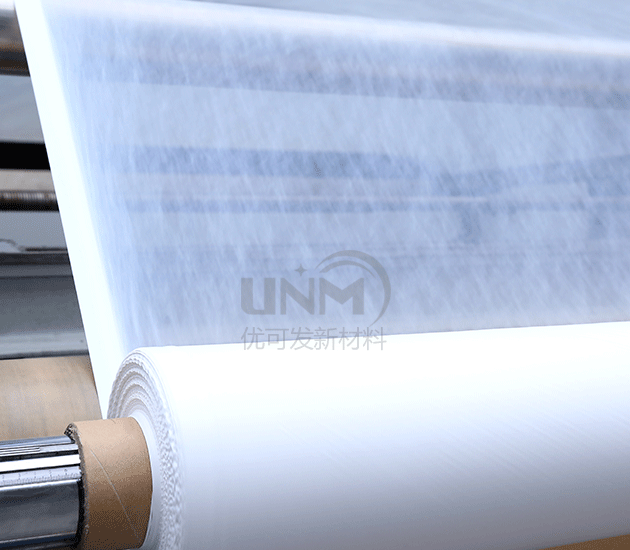

Its manufacturing process usually uses a technique called “stretch blown film”. This technology uses melt extrusion at high temperatures to convert the PTFE material into a film and form a microporous structure. The size of these micropores is usually between 0.1 and 0.5 microns, and the size of the micropores can be controlled or adjusted by performing specific treatments on the PTFE sterile filtration breathable membrane.

It also plays an important role in the field of medicine. As a separation and purification tool, it can be used in cell culture, vaccine preparation, plasma separation and preliminary purification of biochemical preparations in biopharmaceutical manufacturing. During the cell culture process, it can be used for gas regulation and sterility control to ensure the suitability and sterility of the cell growth environment. In vaccine preparation, it can be used to separate and purify proteins and impurities in virus or bacterial extracts, thereby improving vaccine purity and effectiveness. In plasma preparation, impurities such as cells and clots in the plasma can be removed, thereby retaining useful components and improving the quality of the plasma.

In addition to the medical field, PTFE sterile filtration breathable membrane is also widely used in food, semiconductor and environmental protection fields. In food processing, it is used in the production of beverages, beer, dairy products, juice and other products to remove microorganisms and other impurities to improve product quality and stability. In the semiconductor industry, it can be used for gas filtration and particle removal. In the field of environmental protection, it is used in water treatment, oil pollution treatment and air purification.

In short, PTFE sterile filtration breathable membrane is a material with a microporous structure and is widely used in medicine, food, and semiconductors and environmental protection and other fields. It improves product quality by allowing gases to penetrate while preventing the penetration of liquids and microorganisms. Interested parties are welcome to enter the store and contact us.

</p