Open-width washing machine – maintenance and common troubleshooting

How to improve cleaning efficiency, that is, not only improve the washing effect, but also save water, is an important issue in current dyeing and finishing production. At present, the task of cleaning fabrics can be completed in a short time with less equipment and less cleaning agents. This should be studied and solved from two aspects: choosing a reasonable cleaning process and improving cleaning equipment. From the perspective of the cleaning process, factors such as the hardness of the water, the decontamination ability of the cleaning agent, the concentration of the cleaning agent in the lotion, the temperature of the lotion, the fiber properties, the characteristics of the dirt and the cleaning time should be considered. From the perspective of equipment, it is how to maintain a large concentration difference between the washing liquid and the dirt, accelerate the exchange of washing liquid, thin and destroy the solid-liquid phase boundary layer, etc. At present, the main measures taken in this regard include countercurrent cleaning, high-temperature steam cleaning, strong spray rolling (or strong spray suction), mechanical oscillation and extending the cleaning action time.

1. Equipment measures to improve cleaning effect

Figure 4-15 shows a low water level corrugated roller high-efficiency flat washing machine. Its structural characteristics are as follows:

(1) Normal pressure liquid seal hot washing: water along the top cover mouth Sealing, the entrance and exit of the cloth are sealed by lotion, and the temperature in the tank can reach as high as 98°C. The fabric runs in the steam domain for a long time, and this kind of steam cleaning has a very significant effect on washing alkali, washing color phenol and washing reactive dyes. Adopt a better-performing soda-water mixer, add hot water outside the tank (hot water is sprayed on the fabric before entering the rolling point of the roller group), and heat and maintain heat in the tank. This method consumes less steam, keeps the temperature in the tank stable, and makes the fabric less likely to wrinkle. .

(2) Counterflow low water level: In addition to the backflow of washing liquid between adjacent washing tanks, there are also circuitous counterflows in the tanks. At the same time, due to the low water level and small liquor ratio, the washing liquid can be replaced quickly and fully utilized, and it is conducive to the diffusion of dirt on the fabric into the washing liquid, and consumes less water and steam.

(3) Multiple dipping and multiple rolling: A heat-resistant synthetic rubber pressure roller with a diameter of 30mm is installed obliquely on each upper guide roller in the tank, and is pressurized by its own weight to make the fabric multiple dipping and multiple rolling.

(4) Low-frequency oscillation: The middle four passive lower guide rollers in each groove are four-corner cloth guide rollers (i.e., corrugated rollers), which can cause the fabric to oscillate at low frequency and stir the lotion, prompting rapid exchange of lotion on the fabric. .

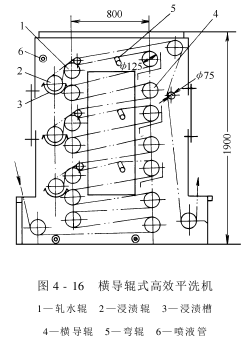

Figure 4-16 shows a horizontal guide roller type high-efficiency flat washing machine. Its structural characteristics are as follows:

① Fabric crossing and washing liquid counterflow: After the fabric enters the washing tank from the bottom of the tank, it crosses from bottom to top between the guide rollers Wear running. Use a pump to pump the lotion with low dirt concentration at the outlet, heat it with a steam-water mixer, then send it to the dipping tank for flushing, and flow through each layer of fabric in a counter-current manner. Because the fabric running across the guide roller changes its running direction multiple times, the counter-current washing liquid is flushed downward from the top of the tank. With its cross-flow effect, it can repeatedly penetrate the fabric from both the front and back sides, which is beneficial to washing. The liquid fully counter-currently exchanges the washing liquid on the fabric, which consumes less water and has high cleaning efficiency.

②Normal pressure liquid seal hot washing: the washing tank is basically sealed, and the fabric inlet adopts a water seal. In addition to using a soda-water mixer to heat the washing liquid, there is a direct steam pipe heating at the bottom of the washing tank. The washing liquid in the tank can be close to the boiling point water temperature under normal pressure.

③Multiple dipping and multiple rolling: In addition to the small dipping tank and rollers installed in the tank, in fact, each cloth guide roller and anti-wrinkle bending roller have a certain squeezing effect, so the fabric is subjected to multiple dipping and multiple rolling. It is used for cleaning when the clear and turbid washing liquid is separated.

④Low water level, small liquor ratio: The liquid level of the large washing liquid tank at the bottom of the washing tank is only 230mm, with a small capacity; the capacity of the small dipping tank is even smaller. Therefore, the lotion is updated quickly, which is conducive to the diffusion of polluting impurities on the fabric into the lotion.

It can be seen that an efficient flat washing machine is often designed after comprehensive consideration of many aspects.

General maintenance and common troubleshooting of flat washing machines are shown in Table 4-4 and Table 4-5.

2. Comprehensive and efficient cleaning equipment

Steam for cleaning The steamer is a type of normal-pressure steaming equipment used for soaping, hot water steaming and alkali removal during fabric coloring and printing post-processing. The purpose of its use is for cleaning. Therefore, its basic structure has some similarities with that of a flat washing machine. However, since this is a steam-liquid two-phase form of steam cleaning, it has a higher temperature and greater penetration, so the cleaning speed and effect are improved. After the normal temperature fabric enters the steaming box and encounters high-humidity steam, its own temperature rises, the fibers expand, and the dirt activity increases.

The condensed droplets of steam attract dirt molecules, reducing their concentration, and are washed away as the fabric enters the washing liquid at the bottom of the steamer. In this cycle, the fabric is washed quickly.

Figure 4 -17 shows the alkali removal steam box, which is used to steam and wash double-layer silk fabrics to remove alkali. There are two rows of cloth guide rollers on the upper part of the steaming and washing box, with 9 cloth guide rollers in each row, of which the even number is the driving roller; the 9 rollers in the second row are smaller than the upper row, and the even number is also the driving roller, and the corresponding cloth guide roller in the row passes through the gear.Move. The lower part of the steamer corresponds to two rows of 10 passive cloth guide rollers. The two rows of cloth guide rollers in the upper steam area use rolling bearings, and their bearing seats are installed outside the side panels of the cast iron box and are separated from the side panels; the bearings of the cloth guide rollers in the lower liquid area use sliding bearings made of nylon or cast iron. bearings.

In order to improve cleaning efficiency, the bottom of the box is a flat bottom that slopes from back to front. A countercurrent partition plate is installed on every two cloth guide rollers. The lower part of the plate is equipped with a direct heating steam pipe to heat the lotion between each partition. There is a drain cock at the bottom of the partition, so the liquid level can be controlled at any time. The steam area part is equipped with a steam nozzle, which can directly heat the steam in the box. Several cold water spray pipes are installed between the guide rollers of the vapor-liquid tank. When a fault occurs, the cold water valve can be opened immediately to cause the spray pipe to spray water, quickly reducing the temperature in the box and handling the fault in time.

After the fabric is washed with boiling water and steamed in the box, the alkali content in the fabric is greatly reduced, but the fabric stretches more. In order to ensure that the fabric runs in a normal state without wrinkles, the diameter of the active cloth guide roller must be arranged in increasing order from small to large, and the increment is determined by experience. For example, for the LM222 de-alkali steamer, the increment of the 125mm active guide roller in the first steamer is 0130mm, and the 100mm active guide roller is 0124mm; the increments of the two in the second steamer are 0120mm and 0116mm respectively.

In order to remove the curls and wrinkles of the fabric entering the box, two active thread expansion rollers should be installed at the fabric entry.

Figure 4-18 shows the soap steaming box, which is used for soaping and hot water steaming of cotton, polyester/cotton and general chemical fiber blended chemical fiber fabrics after coloring and printing. There are three rows of cloth guide rollers installed in the box; 13 in the upper row and odd numbers are driving rollers; 26 small-diameter waist rollers in the middle and 14 guide rollers in the lower row are all passive rollers. The front and rear plates of the cast iron box of the steamer are cast iron steam splints, which are used for indirect heating to maintain the temperature inside the box. Eight direct steam heating tubes coated with mufflers are installed at the bottom of the box to heat the lotion. The steam domain part is equipped with 4 direct steam nozzles for steam injection and steaming.

Figure 4 -19 shows a long steamer. In addition to soap steaming and hot steaming, it can also be used for alkali steaming. The box is equipped with two rows of upper and lower cloth guide rollers, 9 in the upper row, and the odd number are driving rollers, all driven by torque motors alone. There are 10 lower rows, all of which are passive guide rollers.

De-alkali The repair and maintenance precautions for the steamer are shown in Table 4-6 and Table 4-7 respectively.

The maintenance precautions for soap steamers and long steamers can also be found See Table 4-6 and Table 4-7.

AAADFGTEHTRY