Open-width washing machine – loose flat washing machine

Due to the appearance, feel, style and other requirements of silk fabrics, knitted fabrics and some wool-like and silk-like chemical fibers and their blended chemical fiber fabrics, their dyeing and finishing should be carried out in a tension-free state. Therefore, loose-type flat washing machines have made great progress in recent years. Currently, commonly used models include S220-180 loose-type open-width washing machines and loose-type runner open-width cloth washing machines.

Figure 4-7 shows a loose hexagonal roller flat washing machine, which is suitable for pre- and post-processing in the finishing process of medium-length chemical fiber fabrics, such as desizing, scouring, coloring and loose washing after finishing. , can also be used for loose washing or loose coloring of pure cotton or chemical fiber fabrics.

Whole machine It consists of a multi-compartment steaming and washing box. There is a water seal at the entrance and exit of the cloth, which can increase the steaming and washing temperature. Each compartment of the steaming and washing box is driven independently and has a separate washing tank for easy replacement of washing liquid. The steaming and washing box is made of stainless steel plate, and its structure is shown in Figure 4-8. The hexagonal roller used for feeding cloth is shown in Figure 4-9. It is welded with a stainless steel plate with a thickness of 2.5mm and a diameter of 500mm. Both ends can enter the washing liquid. There are multiple rows of circular holes with a diameter of 25mm drilled on the roller surface, which can also allow the washing liquid to enter and exit. When the hexagonal roller pulls the fabric, the lotion naturally flows out of the round hole due to its own weight, and the fabric is detached from the roller surface, folded and stacked on the track, and runs forward along the track in the direction of the lotion flow.

The characteristics of the washing liquid tank circulation exchange are: low liquid level, high flow rate Large and quick to replace. Since the level of the liquid level will affect the folding and washing effect of the fabric, the height of the liquid level is very important, and it is related to the height of the pile of fabrics. Generally, the folding height of fabric is 1/2 of the length of one side of the hexagonal roller, and the liquid level is 1/4 of the height of the hexagonal roller.

In order to ensure that the fabric does not deflect left and right in the washing liquid, it is necessary to ensure that the liquid flow flows regularly along the forward direction of the fabric. The water guide plate can make the liquid flow forward smoothly and prevent the washing liquid from generating vortex when it hits the wall panel, causing the cloth to pile up.

The speed of the hexagonal roller should be 7% to 9% faster than the cloth drop roller, so that it can produce a gentle rubbing action on the fabric. The liquid level also oscillates with the rotation of the hexagonal roller. When the vehicle speed reaches 30m/min, strong oscillations can be induced, which is of great benefit to the loosening and shrinkage of the fabric.

In order to ensure The washing liquid tank of each grid is synchronized, and the cloth capacity of each grid must be controlled. Figure 4-10 shows the schematic diagram of automatic control of fabric volume. Adjust the weight to balance it with the set fabric capacity. When the cloth capacity changes, the stacking track will swing up and down around the fulcrum. Through the connecting rod and the moving rod, this swing is converted into the circumferential movement of the resistance axis, causing the resistance to change and adjust the speed of the vehicle to achieve the cloth capacity. The purpose of automatic control of quantity.

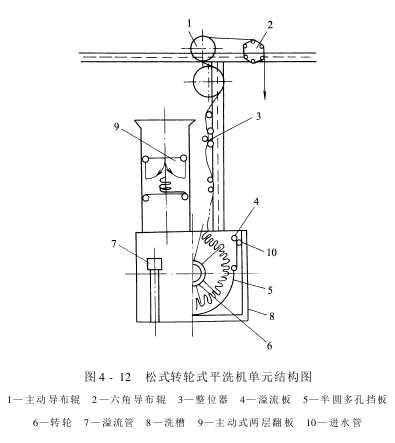

Figure 4-11 shows a loose wheel type flat washing machine. This machine has a simple structure and is easy to operate. It is suitable for desizing and flat washing of medium-length chemical fiber blended chemical fiber fabrics. Figure 4-12 shows its unit structure diagram. The fabric is put into the small flap by the hexagonal cloth guide roller, and after being stacked for 36 seconds, it falls onto the blades of the runner. There are 10 blades in total, with a length of 90mm. The diameter of the hollow shaft of the runner is 300mm, and the shaft surface is covered with small circular holes. Convenient for lotion replacement. After the fabric is soaked and cleaned in the runner groove for 3 minutes, it passes through the thread expansion roller and positioner, enters the active cloth guide roller, runs in an S shape, and enters the next grid.

Figure 4 -13 shows the structural diagram of the friction transmission of the active cloth guide roller. Relying on the adjusting screw, adjusting nut and spring, the torque transmitted by the friction disc can be adjusted to achieve the purpose of controlling the fabric tension.

A forced flushing and suction mechanism is installed at the last stage of the loose flat washing machine (Figure 4-14). It consists of double-layer nylon lining mesh, spray pipe and porous suction mouth. After the fabric is introduced into two layers of crawler-shaped nylon lining mesh, both sides are forced to be washed by the upper and lower spray pipes. The lotion in the fabric is sucked out by the porous vacuum suction port to improve cleaning efficiency.

AAAFYYTRUYJY76I