Cloth in and out device

1. Open-width fabric feeding device

The fabrics in the workshop stacker are basically in a tension-free, folded and stacked state. If the fabric is directly put into the machine for finishing, it will easily produce wrinkles and skew, which will definitely affect the smooth progress of dyeing and finishing and the quality of the printed and dyed products. In order to overcome the above phenomenon, the fabric must be processed by the fabric feeding device before entering the machine for finishing. The purpose is:

(1) Give appropriate tension to the fabric so that the fabric can enter the machine flatly without causing wrinkles .

(2) Guide the fabric to run in the normal position agreed by the machine to prevent the fabric from excessive deviation from left to right.

(3) Make the dust and debris caught in the fabric fall down easily and naturally, or make it easy for the operator to detect and remove it in time, so as to prevent dust and other debris from entering the machine and damaging the rollers or affecting product quality. In addition, if you find that the cloth is knotted or not sewn, you can stop the machine in time to act as a buffer.

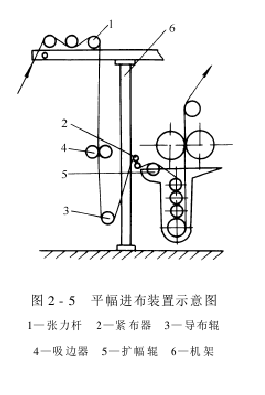

Flat width The fabric feeding device is commonly known as the fabric feeding frame, as shown in Figure 2-5. It is mainly composed of a tension rod (also called a fabric guide tube), a fabric tensioner, an expansion roller, an edge suction device, a fabric guide roller, a frame, etc. The tension rod gives appropriate warp tension to the fabric; the fabric tensioner can not only increase the warp tension of the fabric, but also adjust its warp tension appropriately according to different fabric varieties; the function of the expansion roller is to expand the fabric to prevent wrinkles And wrinkle removal; the function of the edge suction device is to provide weft tension to the fabric to prevent the fabric from curling, and automatically guide the fabric to run in the middle of the machine to prevent the fabric from excessive left and right deviation.

The edge suction device and widening roller in the open-width fabric feeding device will be discussed in detail in the third and fourth sections of this chapter. Here we focus on the structure of the tension rod and fabric tensioner.

1. Tension rod

Generally consists of a set of cloth guide rods (wooden poles or galvanized pipes) fixed on the frame and parallel to each other. Similar to the fixed guide roller, its function is to guide the movement of the fabric and use the friction between its surface and the fabric to increase the warp tension of the fabric.

In order to adapt to the different requirements of different fabrics on the warp tension of the fabric, when changing the fabric type, you can wear more or less cloth guide rods appropriately to adjust the warp tension of the fabric within a certain range. During use, you should always check whether the club face is clean to avoid scratching the fabric, and check whether each pole is level and loose.

2. Fabric tensioner

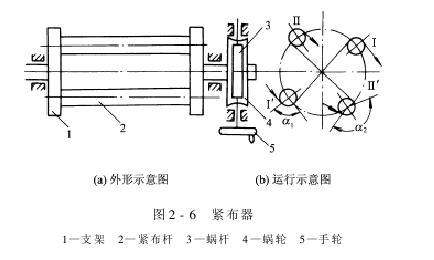

As shown in Figure 2-6(a), the fabric tensioner is a combined adjustable fixed fabric guide roller, which consists of three parts: a bracket, an adjustment mechanism and a fabric tensioning rod.

(1) Bracket: It is a bracket that supports the cloth tensioner. It is composed of a mandrel, a support plate (iron plate or cast iron), a bearing seat and other parts.

(2) Adjustment mechanism: It consists of a set of worm gears and worms. The worm gear is fixed on the support mandrel, and the worm is connected to the handwheel. When the operator turns the handwheel, the worm gear is driven by the worm, causing the support connected to the worm gear to rotate. In this way, the relative positions of the two fabric tightening rods fixed on the bracket also change, that is, the wrapping angle of the fabric on the fabric tightening rod is changed to achieve the purpose of adjusting the fabric tension.

In addition, ratchets, pawls or movable pins are also used as adjustment mechanisms.

(3) Tight cloth rod: as shown in Figure 2-6(b). If the position of the tightening rod is adjusted from I-I′ to II-II′, the wrapping angle of the fabric on the tightening rod will also change from α1 to α2 , obviously α2 >α1, the warp tension of the fabric increases. Therefore, the fabric tensioner can adjust the warp tension of the open-width fabric within a certain range.

Tight cloth The rod is usually made of galvanized pipe (or brass pipe, stainless steel pipe) with a diameter of 50mm. The surface of the tight-fitting rod must be clean and resistant to acid and alkali corrosion. The fabric and the tight fabric rod slide against each other.

2. Open-width fabric dispensing device

Open-width fabric dispensing is mostly done with left and right fabric discharging. The open-width cloth output device is commonly known as the cloth drop frame. Its function is to lead the fabric out of the working machine and swing it at a certain amplitude so that the fabric can be piled neatly into the stacking car.

The open-width cloth discharging device is mainly composed of a traction cloth guide part, a swing cloth drop part, a transmission system, a frame, etc., as shown in Figure 2-7.

1. Pulling and guiding part

The function of this part is to pull and guide the open-width fabric in the previous machine. It consists of an active cloth discharging roller, a cloth pressing roller and a pressure adding and releasing device.

(1) Active cloth discharging roller: The roller body of the active cloth discharging roller is generally made of wood, but it is also made of iron pipes. The roller diameter is generally between 200 and 250mm. Both ends of the roller are fixed with bearings. on the rack. The shaft end of the roller is driven by a pulley or sprocket, and its linear speed is generally about 3% to 5% faster than the fabric. In some cases, it is 15% to 20% faster. The roller surface should be wrapped flatly with a rubber belt or felt belt to increase the friction between it and the fabric to avoid slipping when exporting the fabric.

(2) Pressing roller: The roller body of the pressing roller is made of steel pipe, with chrome plating on the surface. It is also made of wood or copper pipe, with a diameter of 120~125mm. The cloth pressing roller is installed on the active cloth discharging roller and rotates due to friction on the surface of the active cloth discharging roller.

&r> 1. Umbrella handle type fabric storage box

Umbrella handle type fabric storage box is made of angle steel, and the inside is made of hard PVC board and pipe. The fabric capacity is 600~800m, and the fabric storage time can be up to 4~ 5 minutes, ensuring enough time to change the axis (the actual axis change only takes 2 minutes). After changing the shaft, the speed can be increased to finish the remaining fabrics in the box, which will increase the warp tension of the fabric and prevent wrinkles. Before changing the axis, slow down appropriately to store the cloth.

2. Cloth rolling device

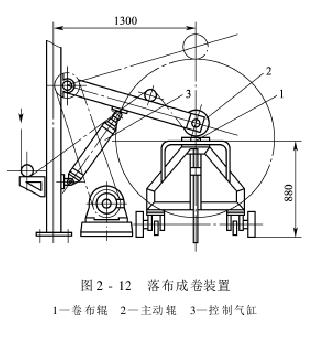

There are many types of cloth rolling devices, but in terms of rolling methods, there are only two types: active cloth rolling device and surface drive cloth rolling device. The surface drive cloth rolling device places the cloth rolling roller on two (or one) driving rubber rollers rotating at a constant speed, and relies on the surface friction of the driving rubber rollers to drive the cloth rolling roller. The active winding device uses a variable speed motor to directly drive the winding roller. That is, as the winding diameter increases, the speed of the winding roller slows down accordingly to keep the winding line speed unchanged.

The surface drive cloth rolling device consists of an active rubber roller for rolling cloth, a lifting rocker arm frame, etc. The active rubber roller on it is pressed tightly behind the cloth rolling roller of the drop-off car, and relies on friction to drive the cloth rolling roller to rotate and roll the cloth. As the diameter of the cloth roll increases, the rocker arm frame and the driving rubber roller also rise. After the roll is filled with the shaft, the machine immediately stops, opens the air valve, and lifts the rocker arm and the driving rubber roller away from the cloth roll.

The surface levelness of the cloth rolling roller, rubber cloth pressing roller (HSA92~98), and cloth guide roller is 5/10000 to ensure the quality of the cloth rolling.

3. Drop cart

Drop cart, also known as cloth rolling cart, is a device used to carry cloth rolls. After the roll is filled with the shaft, it can be lifted and transported by a battery truck.

4. Transmission mechanism

During the rolling process, the motor drives the active rubber roller to run at high speed. Through friction, the fabric is advanced and rolled.

AAASDFWETGD