NO,1

Combed sliver quality index

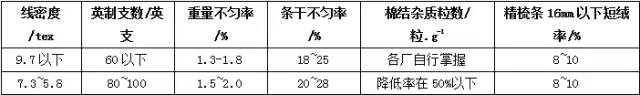

Combed cotton yarn is used to spin high-end products, so the quality requirements for combed slivers are extremely high. Due to the different spinning varieties, raw cotton conditions and production conditions of each factory, the quality index control range of combed sliver is also different. The general control range is shown in Table 1.

Table 1 Quality indicators of combed slivers

NO, 2

Reduce neps and combed yarn defects

Combed cotton yarn has higher quality requirements, and the number of neps and impurities is more than half less than that of carded cotton yarn with the same linear density. The carding machine can remove a considerable amount of neps and impurities, the impurity removal rate can reach 50% to 60%, and the neps can remove 10% to 20%.

To reduce nep impurities and yarn defects, in addition to rationally selecting raw cotton, giving full play to the impurity removal function of the cleaning and carding processes and preventing the occurrence of neps, in addition to the combing process The following points should be noted:

(1) Improve the roll preparation process, improve the quality of the rolls, and strive to improve the longitudinal and transverse uniformity of the rolls and the straightness and parallelism of the fibers degree to give full play to the combing function of the combing machine.

(2) Improving the mechanical condition of the carding machine, especially the condition of the combing needles, is the key to improving the carding effect. For example, the needle specifications and needle planting density of the cylinder and top comb should be reasonably adjusted to prevent needles from being broken or missing, keep the comb needles in good working condition, trim the brushes in a timely manner, improve the flatness of the brushes, and maintain the elasticity of the bristles to improve The working efficiency of the brush ensures that it can clean the cylinder needle surface, etc.

(3) Correctly master the combing process, and reasonably adjust the timing of the separation roller’s forward rotation, the positioning of the cylinder bow plate, the timing of the closing of the nip plate, and the combing distance.

(4) Reasonably grasp and control the combing noil rate. According to the quality requirements of the spun cotton yarn, reasonably determine the noil rate, pay attention to the status of the noil at any time, and reduce the table difference and eye difference of the noil.

(5) Strengthen operational management. During operation, attention should be paid to the sticking of small rolls to prevent unclear layers or damage to the combing needle when feeding thick layers, which will affect the quality of the cotton web. At the same time, the cleaning cycle of various parts of the combing machine is correctly formulated and implemented, and better pile board structures and materials are used to reduce combing yarn defects.

NO,3

Reduce the evenness of combed sliver

Due to the periodic separation and combination of the cotton web output from the combing machine, the combed slivers have large periodic segment unevenness. After the combining effect of the subsequent process, the periodic unevenness of the combed sliver can be greatly reduced, and because the separation and straightening parallelism of the fibers in the combed sliver are better, there are less short lint and defects, which is beneficial to Due to the drafting process in the subsequent process, the combed sliver has better evenness.

There are many factors that affect the evenness of combed sliver. On the basis of improving the quality of small rolls and maintaining normal organizational status, the following points should also be paid attention to:

p>

(1) Reasonably adjust the process parameters and correctly time the positioning;

(2) Correctly control the tension and drafting of each part, Reduce accidental elongation;

(3) Keep the passage through which cotton webs and slivers pass through smooth and clean;

(4) Strictly control the temperature and humidity of the workshop so that the temperature and humidity of the workshop are controlled within the specified range, that is, the temperature is 20 ℃ ~ 30 ℃ and the relative humidity is 55% ~ 60%, so as to avoid improper temperature and humidity control to prevent rubber rollers, winding rollers, and cotton nets from being damaged due to improper temperature and humidity control. Problems such as broken edges and clogged inclined pipes.