Twisting is a necessary means to form yarn

Twisting is to cause the two sections of the yarn to rotate relative to each other. The original fibers parallel to the yarn axis are tilted into a spiral. For short fibers, twisting is mainly to increase the strength of the yarn. The twisting of filament can both improve the

The strength of the yarn can also produce a certain effect. The amount of twisting of the yarn and the combination of the twist direction and twist of the yarn in the fabric have a great impact on the appearance and performance of the product.

Indicators of twisting properties include: twist degree indicating the degree of twisting, twist coefficient and twist direction indicating the direction of twisting.

01

Twist T

Twist: the number of twists per unit length of yarn. The yarn is twisted once by adding a twist angle to form a twist.

- Ttex – special twist (twist/10 cm, used for cotton yarn)

- Tm – metric twist (Twist/m, combed wool yarn and chemical fiber filament)

- Te – British twist (twist/inch)

1 inch =2.54 cm, Ttex=0.1 Tm=3.937 Te

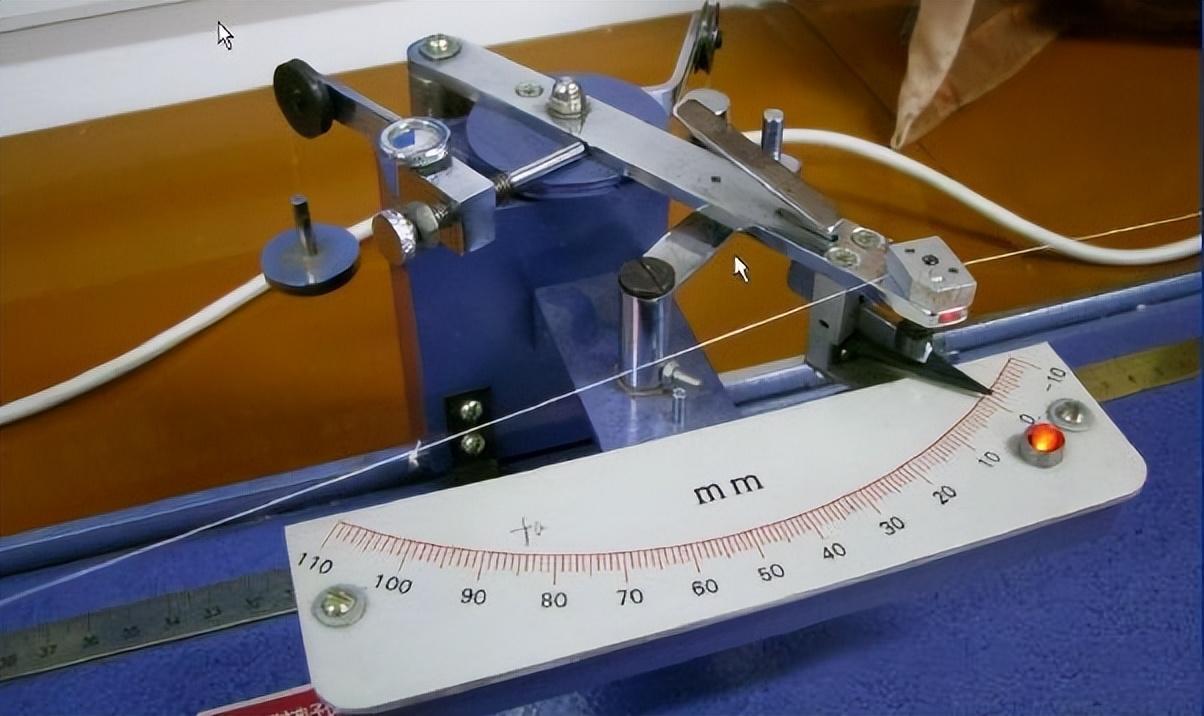

Measuring method of twist

The commonly used twist testing methods in my country include direct counting method and untwisting and twisting method. Short fiber and strand tests generally use the direct counting method, while spun yarns use the untwisting and twisting method. In addition, there are secondary and triple untwisting and twisting methods, slipping methods, etc.

1 Direct counting method

Under a certain tension, clamp both ends of the yarn of known length and fix one end , the other end rotates around the axis in the untwisting direction until the single yarn or single fiber in the strand or the single fiber in the multifilament is completely parallel. The number of twists removed is the number of twists in the length of the yarn sample

2 Untwisting and twisting method

Under a certain tension, Clamp the two ends of the known yarn length, fix one end, and rotate the other end around the axis in the untwisting direction to measure the number of twists when it returns to the starting length after untwisting and reverse twisting. The number of twists is the yarn. The length of the wire specimen is twice the length of the twist.

Twist affects the strength, rigidity, flexibility, elasticity and shrinkage of yarn. As the twist of the yarn increases, its strength increases, but the twist cannot exceed a certain value, otherwise its strength will decrease. This certain value is called the critical twist of the yarn. Yarns of different raw materials have different critical twists. Generally, under the premise of meeting the strength requirements, the smaller the twist of the yarn, the better, because the increase of twist will make the yarn feel harder, the elasticity decreases, and the shrinkage increases. This is why filament yarns generally try not to twist or twist as little as possible. Because of the twist.

In addition, the twist also affects the volume weight and diameter of the yarn. The twisting effect increases the tightness of the yarn. Within a certain range, the volume weight of the yarn increases with the increase in twist, and the diameter of the yarn decreases with the increase in twist, thus causing changes in the coverage and comfort of the fabric.

Yarn twist should be selected according to different fabric uses.

- The warp yarn needs to have higher strength and the twist should be larger

- The weft yarn and knitting yarn need to be soft and the twist should be smaller

- The yarn used for woven and knitted fleece fabrics should have a smaller twist to facilitate fleece

- Thin and crisp crepe fabrics are required to be smooth, stiff and refreshing. The twist of the yarn should be larger

02

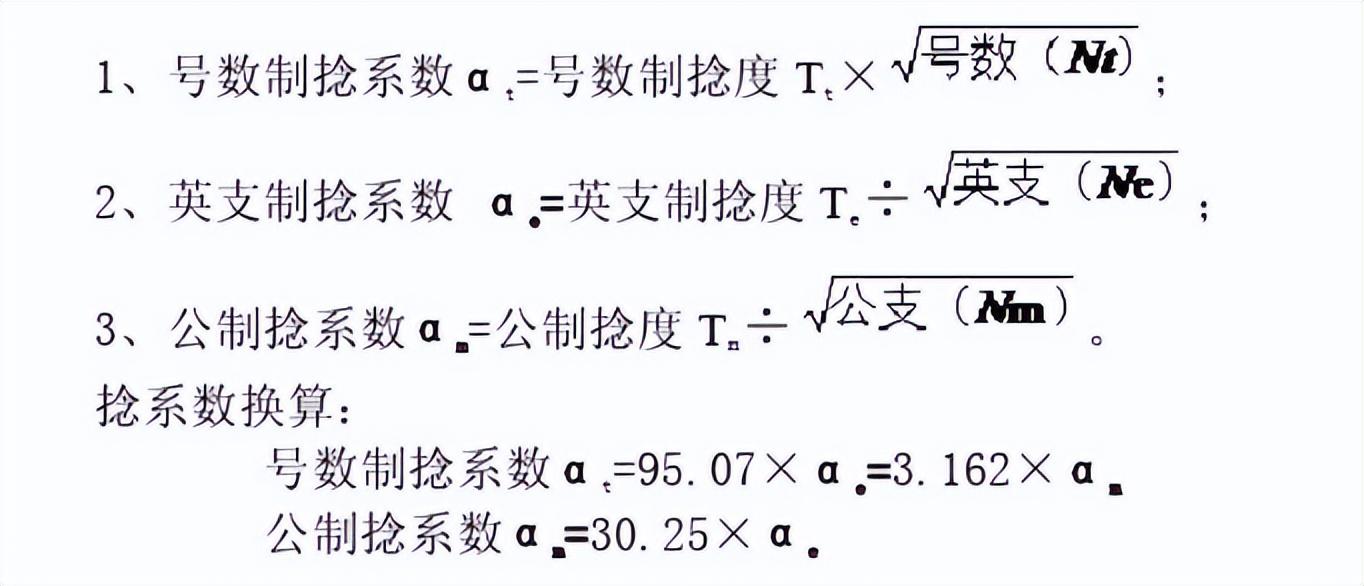

Twist coefficient

Twist cannot be used To compare the twisting degrees of yarns of different thicknesses, because with the same twist, the fiber tilt of thick yarns is greater than that of thin yarns. In actual production, the twist coefficient is often used to express the degree of twist of the yarn.

The twist coefficient can be calculated based on the twist of the yarn and the linear density of the yarn.

The twist coefficient is a relative value that combines the linear density to indicate the degree of twisting of the yarn. It can be used to compare yarns of different thicknesses. Degree of twist. The larger the value, the greater the degree of twist.

The choice of twist coefficient: mainly determined by the properties of the raw materials and the use of the yarn.

- When spinning with slender fibers, the twist coefficient of the yarn can be lower

- When spinning with thick and short fibers, the twist coefficient The coefficient should be higher

- The warp yarn needs higher strength and the twist coefficient should be larger

- Weft yarn and knitting yarn generally need to be soft, and the twist coefficient should be smaller

- The twist coefficient of yarn used for woven and knitted raising should be small to facilitate raising

- Thin fabrics and knitted outerwear fabrics are required to have a smooth and crisp style, and the yarn twist coefficient should be larger

- The yarn fineness is different, and the twist coefficient is also different. The twist coefficient of fine yarn should be Larger

The roving twist coefficient of general chemical fibers is smaller than that of pure cotton. When spinning cotton-type chemical fibers, it is 50% to 60% of that of pure cotton. When spinning medium-length chemical fiber, it is about 40% to 50% of spinning pure cotton. The specific data should depend on the type and quantity of raw materials.

Generally, the twist coefficients of conventional yarns are as follows: ring-spun woven yarn 360~400; ring-spun knitted yarn 320~360; ring-spun low-count pile yarn 280~320; air spinning 400~440.

03

Twist

The twist direction refers to the inclined direction of the fibers in the single yarn or the single yarn in the strand after the yarn is twisted. . It is divided into two types: Z twist and S twist. After twisting, the twisting direction of the yarn is from the lower right corner to the upper left corner, and the tilting direction is consistent with the middle of the “S”, which is called S twisting or smooth twisting; the twisting direction of the yarn is from the lower left corner to the upper right corner, and the tilting direction is consistent with the “S” If the middle part of “Z” is consistent, it is called Z twist or backhand twist. Generally, single yarns often use Z twist, and strands use S twist.

The twist direction of the strands is represented by the twist directions of successive twists. For example, if the single yarn is Z-twisted, the first twist is S-twist, and the second-twist is Z-twist, the twist direction is represented by ZSZ.

The twist direction of the yarn has a great influence on the appearance and feel of the fabric. By matching the twist direction of the warp and weft yarns with the fabric structure, we can weave various styles of appearance, feel, etc. Different fabrics.