The composite process of compost film is to bond film layers of different materials together through hot pressing to form a multi-layer structure. The following are common composite process steps:

1. Material preparation: Prepare films of different materials for lamination, usually including plastic films, Reinforcements and other additives.

2. Cleaning and treatment: Ensure that the compost film surface is clean and dust-free, and perform required treatment, such as electrostatic precipitating or surface activation agent treatment.

3. Heating and preheating: Heating film layers of different materials to appropriate temperatures to make them soft and plastic.

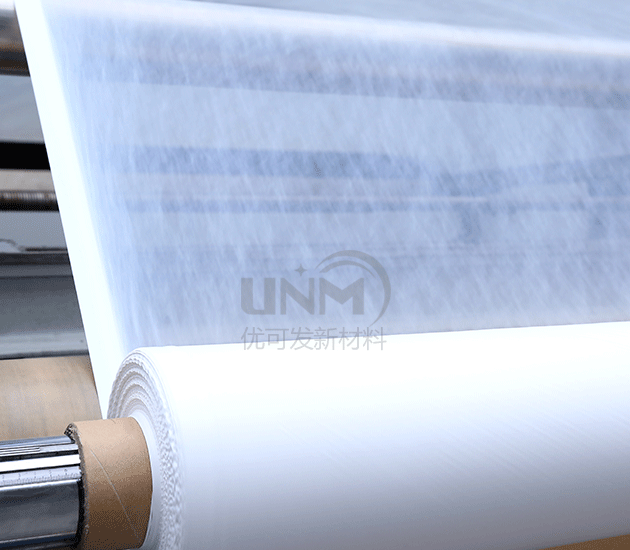

4. Lamination: Stack the preheated compost film layers together in the designed order. These layers may include base layers, reinforcement material layers, and functional layers (such as vapor permeable layers).

5. Hot pressure bonding: Feed the stacked compost film into a hot press, and apply heat and pressure Make the film layers stick to each other. During the hot pressing process, the molecular structure of the material changes, forming a strong bonding interface.

6. Cooling and solidification: After hot pressure bonding, it goes through a cooling stage to solidify and maintain the required structural stability.

7. Cutting and packaging: Cut the composite compost film as needed and package it for easy transportation and packaging. use.

In the composite process of compost film, temperature, pressure and time are key parameters, which need to be based on the characteristics and requirements of different materials. for optimization and control. In addition, other functional layers or additives, such as antibacterial agents, can be added to the composite process according to specific application needs to provide additional performance and protection. Interested parties are welcome to enter the store and contact us.

</p