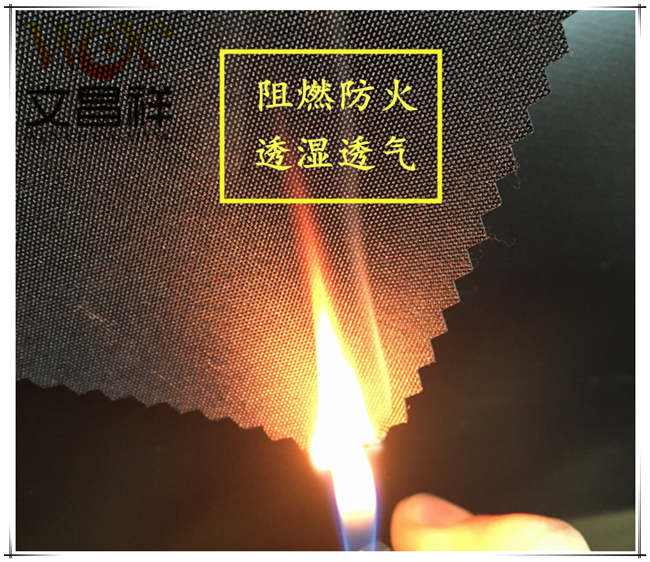

There are many combustion principles of flame retardant Oxford cloth. The basic principles include surface coverage flame retardant, condensed phase flame retardant, gas phase flame retardant, endothermic flame retardant, and droplet effect.

Surface covering Flame retardant: Using some substances that melt when heated and can form a protective film on the fiber surface after cooling, the fire-retardant and flame-retardant cloth can produce non-flammable gas when heated to isolate the air on the fiber surface and hinder the supply of oxygen, thereby achieving the flame retardant effect.

Condensed phase flame retardant: Use flame retardants to affect the decomposition process of fibers and reduce the generation of flammable gases. This method is especially suitable for cellulose fibers.

Vapor phase flame retardant: During the combustion process, a large number of free radicals are generated. Adding inhibitors can prevent the spread of flames through free radicals.

Endothermic flame retardant: Through the endothermic reaction of the flame retardant during combustion, it absorbs more heat and reduces the temperature of the burning area to achieve the purpose of flame retardancy.

Melting droplet effect: Chemical fibers such as nylon and polyester will melt and shrink when heated, reducing the surface area, or dripping away from the fire source, hindering combustion.

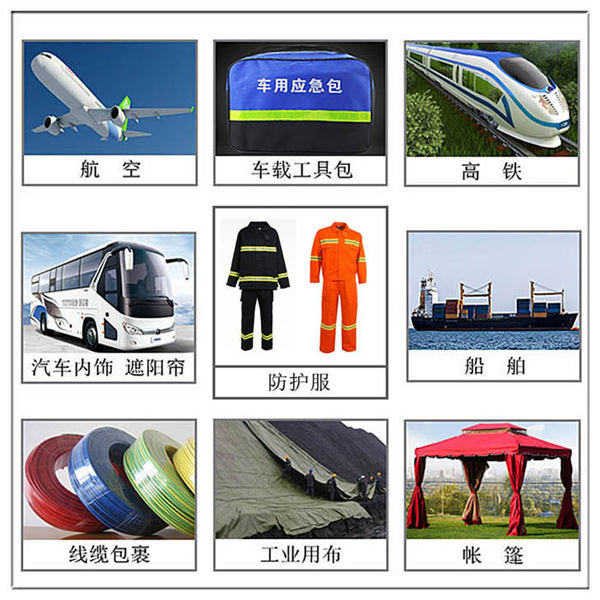

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., which have temporary flame-retardant effect and semi-permanent effect. It has both waterproof and flame retardant effects and durable flame retardant effects. It can also have waterproof, flame retardant, PVC/PU coating, silver coating, composite and other treatments according to customer needs. You can contact the online customer service on the web page or leave a message. We will meet all your needs with the most dedicated service!

</p