Polytetrafluoroethylene ultrafiltration membrane is a new membrane separation technology made of polytetrafluoroethylene material with high efficiency. It has the characteristics of high filtration, high selectivity and corrosion resistance, and is widely used in water treatment, chemical industry, biology and other fields.

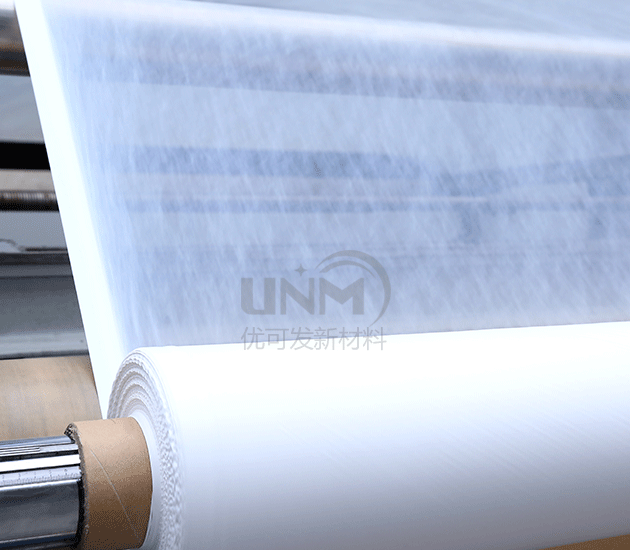

The material preparation process mainly includes the following steps: first, mix polytetrafluoroethylene resin with solvent to form a polymer solution , and then the polymer solution is coated on the substrate through methods such as spin coating and dip coating, and then dried and cured to form a polytetrafluoroethylene ultrafiltration membrane.

The material has a porous structure and can well separate substances of different molecular weights. Its main features are as follows:

1. It has excellent separation efficiency and flux, and can well remove microbial contamination such as suspended solids, colloids, and bacteria in the water. things.

2. The pollutants can be separated according to their molecular weight and shape to achieve high selectivity.

3. It has good corrosion resistance, is not easily damaged by chemicals such as acids, alkalis, and salts, and has a long service life.

4. Can be used in a wide temperature range and is suitable for different industrial fields and application scenarios.

5. It is not easy to deposit impurities and is easy to clean and maintain.

Polytetrafluoroethylene ultrafiltration membrane has been widely used in water treatment, chemical industry, biology, environmental protection and other fields. For example, in drinking water treatment, it can remove microorganisms, colloids, suspended solids and other pollutants in the water to improve the quality of the water; at the same time, in the pharmaceutical process, it can also be used in purification, concentration, separation, etc. to improve product quality and Yield. Interested parties can enter the store for consultation.

</p