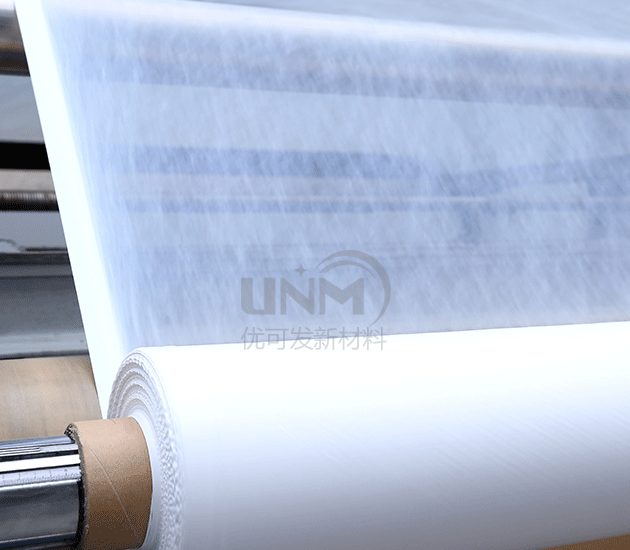

PTFE (polytetrafluoroethylene) microporous filter membrane is a high-filtration effect filter medium widely used in pharmaceutical production. PTFE microporous filtration membrane has excellent chemical inertness, corrosion resistance, abrasion resistance and temperature resistance, so it performs well in the pharmaceutical production process.

In the pharmaceutical production process, filtration and separation technology are crucial. It can filter out impurities, bacteria, viruses and other tiny substances in the pharmaceutical production process, improving the purity and reliability of pharmaceuticals. In addition, compared with other filter media, it also has the following advantages:

1. Excellent chemical stability: Due to its chemical inertness, it can be used in various It can be used in acid, alkali and organic solvent environments and will not be affected by chemical effects.

2. High temperature and high pressure tolerance: ptfe microporous filter membrane can operate at very low or high temperatures and pressures Works without deformation or damage, making it ideal for pharmaceutical production processes that handle high-temperature, high-pressure conditions.

3. Superior physical properties: The physical properties of this film are very stable and not easily damaged or deformed. In addition, it has good wear resistance and water resistance, so it can be used stably for a long time.

</p