Dust removal Ventilation and dust removal methods

The equipment that collects dust from the dusty air is called a dust removal device. Dust removal devices are divided into two categories: dry and wet. The so-called wet dust removal uses water or other liquids to moisten the dust particles in the dusty air, thereby achieving the purpose of capturing dust particles. The so-called dry dust removal uses the gravity, inertial force, centrifugal force, etc. that act on dust particles to collect dust particles.

Ginning plants often use dry dust removal devices in order to recover useful fibers. Because each factory has a different length of construction and different scale, the dust removal equipment used is also different. There are cyclone dust collectors (Sakron), dust cage dust filters, pre-separators and MCZF type dust removal units, etc. The old ones also include gravity settling chambers and bag dust collectors.

1. Cyclone dust collector

Cyclone dust collector (Figure 11-11), also known as Shakron, is made of tinplate and its structure consists of a cylinder, a cone, an exhaust pipe, an air inlet and an ash hopper . The cylinder, cone, discharge pipe and ash discharge port are located on the same axis. It uses the inertial centrifugal force acting on the dust particles to separate the dust from the gas when the dust-containing airflow rotates. When the dust-containing air enters tangentially along the downward spiral inlet at a high speed, it flows between the inner and outer cylinders. During the top-down spiral rotation, larger dust particles are thrown to the inner wall of the cylinder under the action of centrifugal force, where they rub and collide with the wall and lose speed. Under the action of gravity and top-down airflow, , fall to the bottom and be discharged from the ash hopper. The purified air gradually moves closer to the center of the cone as the cone part shrinks. When it is close to the bottom, it is blocked by the bottom and rotates upward to form a rewinding airflow, which is then discharged from the exhaust pipe.

The advantages of this kind of dust collector are simple structure, convenient production, low cost, small footprint, and convenient maintenance and management. If the building area is limited, it can also be installed outdoors, especially when fire enters the dust collector. It is helpful to prevent the spread of fire and has obvious safety effect. The purification efficiency for dust of 20 to 30 μm can reach more than 95%, and it is an efficient dust collector that many manufacturers are willing to adopt. However, the resistance of this dust collector is relatively large, that is, the power consumption is relatively high and the operating cost is high. Although the dust removal efficiency is higher than that of the gravity sedimentation chamber, it is difficult to completely purify the fine fibrous dust. Therefore, the cyclone dust collector is mostly used as a multi-stage dust collector. Primary dust collector in dust collection. Since the cyclone dust collector is a high-pressure dust removal equipment, it is not suitable for low-pressure networks such as cotton collection and lint collection. When the air volume is large, several sacrons can be used in parallel, and the diameter should not be too large.

When using a cyclone dust collector, you should pay attention to:

(1) The inlet wind speed of Sakron should not be too large to avoid increasing resistance, nor should it be too small to avoid affecting the dust removal efficiency. Generally, it is appropriate to control it at 10~16m/s.

(2) When making, the center of the exhaust pipe, the center of the cylinder, and the center of the cone should be on a vertical line to avoid affecting the exhaust effect.

(3) Pay attention to the sealing of the bottom. When cleaning continuously, use the air choke valve and pay attention to check whether the rubber has fallen off. The rotation speed of the choke valve cannot be too high. When cleaning dust regularly, pay attention to the sealing of the bottom to prevent air leakage.

(4) When several sacrons are used in parallel, an even number should be adopted, and the sum of the cross-sectional areas of each branch pipe should be equal to the cross-sectional area of the main pipe.

(5) The angle between each branch pipe should not be too large, generally no more than 30°.

2. Pre-separator

The pre-separator (Figure 11-12) is a piece of equipment that combines the principles of sacron and bag dust removal. The advantage of the pre-separator is that fine dust and most of the air are discharged through the screen. Medium and coarse fibrous dust is blocked on the inner surface of the screen, and continues to rotate downward with a small amount of air, and is removed by the dust lint. Discharged from the waste outlet, useful fibers are easy to clean and recycle. Changing the mesh number of the filter can effectively recycle dust and lint from all aspects of the cotton finishing plant with less resistance. The disadvantage is that the dust removal efficiency is low, so it is generally used as a pretreatment for secondary dust removal. .

3. Dust cage dust filter

Dust cage dust filters come in two forms: standing and horizontal. Cotton finishing plants usually use standing dust cage filters, as shown in Figure 11-13. The dust cage dust filter has a simple structure, is not easy to burn, is easy to use, has a large air volume, and has a small resistance, generally 150 to 200 Pa, and saves an area. Its disadvantage is that dust cages generally use wire mesh as the filter material, and due to the holes, Larger, short fibers and fine dust are easier to pass through, which not only loses fibers, but also increases the burden of cleaning and recycling, affecting dust removal efficiency. Therefore, it is only suitable for handling dust with slightly longer fluff and larger particles, and is more suitable as a primary dust removal equipment.

The dust removal efficiency of the dust cage dust filter depends on the specifications of the mesh. The mesh is large and the resistance is small, but the dust removal efficiency is low. The mesh is small and the dust removal efficiency is high, but the resistance is large. In addition, the exhaust resistance also increases with the increase of the filtering wind speed on the dust cage surface. The specifications of the dust cage dust filter can refer to the following values:

When the gin machine is brushing and exhausting, the filtration wind speed can be 1100~1400m3 /hm2, and 24 holes/25.4mm galvanized low carbon can be used Wire cloth. When stripping machine side velvetWhen ventilating, the filtration wind speed can be 900~1200m3/hm2, and (28~32) holes/25.4mm galvanized low carbon steel wire cloth can be used.

4. MCZF type dust removal unit

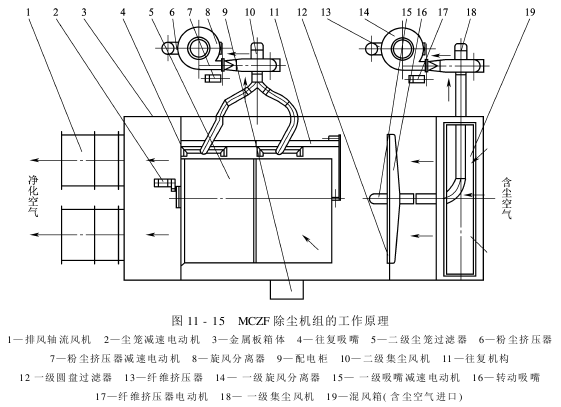

MCZF type dust removal unit is box type, with a light steel structure as the outer casing. It consists of a mixing air box, a pre-separator disk for primary filtration, a primary fiber recovery system, and a secondary dust cage. It consists of filtration (including reciprocating suction nozzles), secondary dust collection system, main exhaust fan and transmission mechanism. It is a new type of dust removal equipment. This dust removal unit is suitable for filtering and purifying air containing fibrous dust, and can recycle effective fibers. The dust concentration of the filtered air can meet the national emission standards.

This unit mainly has the following features:

(1) Good dust filtration effect and high dust removal efficiency.

(2) The processing air volume is large and the resistance is small.

(3) The first-level disc filter and the second-level dust cage filter are concentrated in the metal box with a compact structure, which overcomes the shortcomings of previous dust removal systems in the cotton finishing industry such as large size, large investment, and large floor space. A special dust room needs to be set up.

(4) The filter material is made of stainless steel mesh, which has good fire resistance.

(5) The first-level disc filter can separate long fibers for recycling, and the short fibers collected by the second-level dust cage filter can be made into three-line velvet after processing, turning waste into treasure.

(6) To achieve electromechanical integration, the equipment can be started individually or linked. The equipment is equipped with a pressure monitoring system to promptly adjust the working conditions within the system.

(7) Easy to operate and easy to manage. The operation only requires a start button. The equipment has a viewing window and a work light inside the box, so you can watch the operation of the unit at any time.

(8) Installation and maintenance are convenient and quick. This unit has a disassembly and assembly structure. The box body and dust cage are all connected with screws. It has a reasonable structure and is easy to disassemble and assemble. The transmission parts are not hidden, there are few wearing parts in the machine, and maintenance is simple and easy, which reduces the labor intensity of maintenance work.

This unit overcomes the shortcomings of the previous use of positive pressure dust filtration in the cotton finishing industry. It uses the principle of negative pressure to filter to achieve the purpose of air purification.

When working, dusty air enters the air mixing box in front of the first-level disc filter, and the fibers and large dust are removed through the disc filter. The disc filter and the unit box are sealed and fixed together. The continuously rotating rotating suction nozzle will suck out the fiber dust trapped on the disc filter, and will be sucked by the first-level dust collection fan to the first-level cyclone separator. They are recovered separately and discharged from the fiber extruder.

The dusty air filtered by the disc filter enters the secondary dust cage filter. The air is filtered twice from the outside to the inside. The filtered purified air is directly discharged by the exhaust axial flow fan. The filtered short fibers and dust are sucked out by the reciprocating suction nozzle, sucked by the secondary dust collection fan to the secondary cyclone separator for separate recovery, and discharged by the dust extruder.

The process of MCZF dust removal system is shown in Figure 11-14, and the working principle of MCZF dust removal unit is shown in Figure 11-15.

AAAJH. LK‘PO[IUYUKT