Global market analysis and insights: Flame retardant fabric industry

Flame retardant fabric industry

Abstract: The present invention relates to the technical field of energy-saving doors and windows, and discloses a flame-retardant breathable fabric and a preparation method thereof, which includes the following steps: S1: Prepare materials. The materials include: 4-7 parts of modified ramie fiber, 5 parts of polyester fiber -8 parts, 7-12 parts of silk fiber and other materials; the invention also discloses a flame-retardant breathable fabric, which includes a flame-retardant fabric, a silk antibacterial breathable fabric and a base fabric. The upper surface of the flame-retardant fabric is provided with a flame-retardant composite material, and the flame retardant compound is evenly distributed. The present invention can not only ensure the breathability and heat dissipation performance of the base fabric, but also improve the shape retention of the base fabric through the addition of polyester fiber, and can also make it have good flame retardant performance and air permeability, and at the same time improve the comfort of the flame retardant and breathable fabric. , can also further improve the flame retardant performance of the flame retardant layer.

Technical points

1. A method for preparing flame-retardant breathable fabric, characterized in that the preparation method includes the following steps:

S1: Prepare materials, including: 4-7 parts of modified ramie fiber, 5-8 parts of polyester fiber, 7-12 parts of silk fiber, 5-10 parts of cotton fiber, 5-9 parts of Nomex fiber, polyimide 10-12 parts of 2080 fiber, 5-13 parts of modified glass fiber, 10-15 parts of flame-retardant composite, 10-15 parts of adhesive, 10-12 parts of antibacterial fiber;

S2: Make flame-retardant fabrics by placing warp Nomex fiber, modified glass fiber and weft polyimide 2080 fiber in a loom for weaving to obtain a heat-insulating flame-retardant fabric;

S3: Apply the material and apply the flame-retardant compound to one side of the flame-retardant fabric woven in S2 to obtain a new heat-insulating flame-retardant fabric;

S4: Make breathable fabrics by placing warp silk fibers, antibacterial fibers and weft cotton fibers in a loom for weaving to obtain silk antibacterial breathable fabrics;

S5: Make a base fabric, put the warp modified ramie fiber and weft polyester fiber into a loom for weaving to obtain the base fabric;

S6: Base fabric treatment. The base fabric in S6 is bleached and dyed, wrinkled, and dried in a dryer to obtain the treated base fabric;

S7: Apply adhesive, place the heat-insulating and flame-retardant fabric in S3 and the base fabric in S6 in the rubber roller, and apply the adhesive on the surface of the heat-insulating and flame-retardant fabric and base fabric;

S8: Bonding, with heat-insulating and flame-retardant fabric as the surface layer, silk antibacterial and breathable fabric as the middle layer, and base fabric as the bottom layer. An embossing machine is used for hot pressing to obtain a flame-retardant and breathable fabric;

S9: Rolling, the heat-pressed flame-retardant breathable fabric in S8 is air-cooled, trimmed, and rolled.

2. A method for preparing flame-retardant and breathable fabrics according to claim 1, characterized in that the antibacterial fiber in S1 is mixed with an antibacterial agent and a dispersant and a fiber matrix resin, and then melt-spun to obtain the antibacterial fiber. The antibacterial agents include monohalogenated cyanuric acid, diaminohalogenated alkanes, alkenyl halides, and epoxyhalogenated alkanes.

3. A method for preparing flame-retardant breathable fabrics according to claim 1, characterized in that the flame-retardant compound in S1 consists of hexafluorobutyl methacrylate, phosphate monomer, aminoolefin compounds and oxidation After the graphene is mixed, stir evenly, then heat to 96°C under nitrogen protection, then add chloroplatinic acid isopropyl alcohol solution, react for 5 hours, and obtain it after treatment.

4. A method for preparing flame-retardant breathable fabrics according to claim 1, characterized in that the modified glass fiber preparation raw materials in S1 include nano-silica, nano-alumina, nano-calcium oxide, nano-zirconia, Nano boron oxide, nano iron oxide, nano hydrogen oxide, nano lithium oxide, nano sodium oxide, epoxy resin, toughening agent, the toughening agent is butyl recycled rubber.

5. A method for preparing flame-retardant and breathable fabrics according to claim 1, characterized in that the modified ramie fiber in S1 is made by placing etherified ramie fiber in a mixed solution at 50° C. for 5 hours and then washing with water. , washed with absolute ethanol, and then washed with water until neutral, to obtain modified ramie fiber, in which the mixed solution is composed of amino-terminated polysiloxane, sodium bicarbonate and absolute ethanol.

6. A flame-retardant breathable fabric, including a flame-retardant fabric (2), a silk antibacterial breathable fabric (4) and a base fabric (6), characterized in that the upper surface of the flame-retardant fabric (2) is provided with a flame-retardant fabric. Compound (1), and the flame-retardant composite (1) is evenly distributed, and the flame-retardant fabric (2) includes Nomex fiber (7), modified glass fiber (8) and polyimide (2080) fiber (9) ), and the flame-retardant fabric (2) is woven from Nomex fiber (7), modified glass fiber (8) and polyimide (2080) fiber (9), and the silk antibacterial breathable fabric (4) includes silk fiber (10), antibacterial fiber (11) and cotton fiber (12), and the silk antibacterial breathable fabric (4) is woven by silk fiber (10), antibacterial fiber (11) and cotton fiber (12), and the antibacterial breathable fabric (4) is made of silk fiber (10), antibacterial fiber (11) and cotton fiber (12). burning fabric (2) and�Composition.

The invention also discloses a flame-retardant breathable fabric, which includes a flame-retardant fabric, a silk antibacterial breathable fabric and a base fabric. The upper surface of the flame-retardant fabric is provided with a flame-retardant compound, and the flame-retardant compound is evenly distributed. The flame-retardant fabric includes Nomex fiber, modified glass fiber and polyimide fiber, and the flame-retardant fabric is woven from Nomex fiber, modified glass fiber and polyimide fiber. The antibacterial and breathable silk fabric includes silk fiber, antibacterial fiber and polyimide fiber. fiber and cotton fiber, and the silk antibacterial breathable fabric is woven from silk fiber, antibacterial fiber and cotton fiber, a first adhesive is provided between the flame retardant fabric and the silk antibacterial breathable fabric, and the flame retardant fabric and silk antibacterial The breathable fabrics are fixedly connected through the first adhesive.

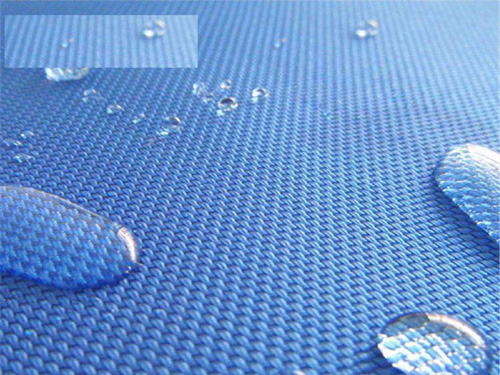

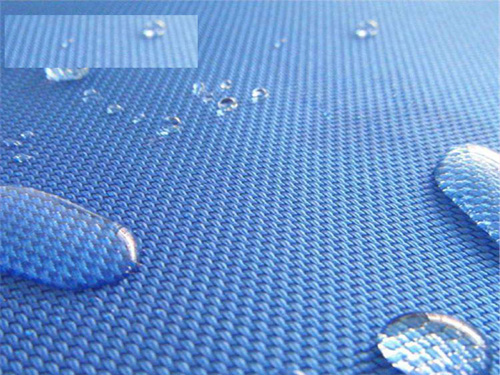

As a further solution of the present invention, the base fabric includes modified ramie fiber and polyester fiber, and the base fabric is woven by modified ramie fiber and polyester fiber.

Further, a second adhesive is provided between the base fabric and the silk antibacterial and breathable fabric, and the base fabric and the silk antibacterial and breathable fabric are fixedly connected through the second adhesive.

(3) Beneficial effects

Compared with the existing technology, the present invention provides a flame-retardant breathable fabric and a preparation method thereof, which has the following beneficial effects:

1. The present invention selects modified ramie fiber with good air permeability as the main fiber to ensure the air permeability and heat dissipation performance of the base fabric. By adding polyester fiber, the shape retention of the base fabric is improved, and the ramie fiber is modified to improve the heat dissipation performance. Its elasticity, cohesion and spinnability.

2. The present invention forms a double flame-retardant protection mechanism through the surface layer of heat-insulating flame-retardant fabric and the flame-retardant compound applied on its surface, which greatly increases the flame-retardant performance of the fabric. At the same time, the silk antibacterial and breathable fabric is woven from natural cocoon silk. It has good breathability and flame retardant properties.

3. The flame-retardant compound in the present invention is a linear polymer with a large relative molecular weight, low mobility, excellent flame-retardant performance and durability, and the cage-like phosphate ester structure in the flame-retardant compound is more likely to be enriched on the surface of the composite material , forming a dense protective carbon layer to prevent dripping or holes, further improving the flame retardant performance of the flame retardant layer.

4. The modified glass fiber in the present invention improves the shortcomings of traditional glass fiber in terms of brittleness and poor wear resistance. The finished flame-retardant breathable fabric made of modified glass fiber has excellent flexibility, comfortable to wear, and improves the wear resistance. The comfort of flame retardant breathable fabric.