Burn-out fabric is also called burnt-out fabric. It refers to the printing that shows patterns after using chemicals to destroy a certain fiber component in blended, twisted or interwoven fabrics. Craftsmanship.

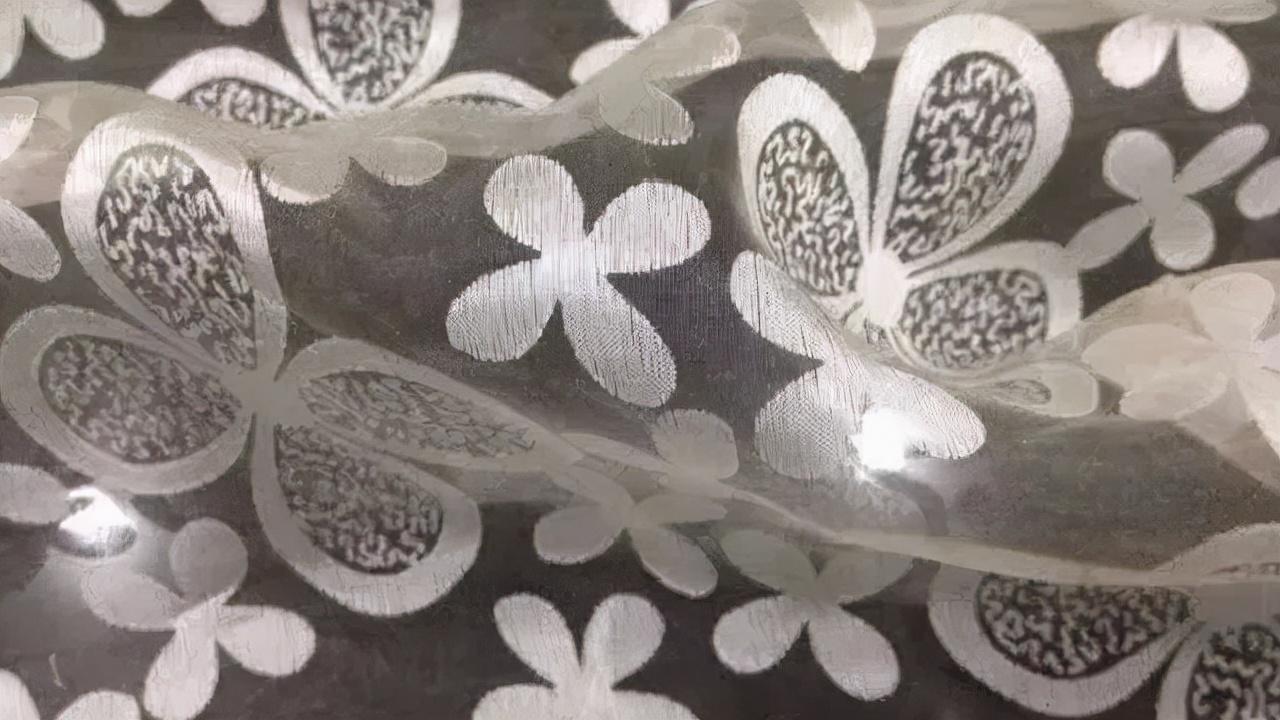

Burn-out fabric pattern

The surface of burnt-out fabric is uneven, with prominent patterns, clear outlines, smooth feel and translucent visual sense. It can be rotted to reveal patterns, or it can be rotten to remove the base plate to reveal raised patterns.

Common burnout fabrics include burnout velvet, burnout cotton and silk interweave, burnout Floral polyester-cotton interweave. Burnout fabrics are generally used in home decoration, bedding and other fabrics.

Burnout printing was first used on silk interwoven fabrics, such as burnout silk, burnt-out velvet, and later used in burnt-out polyester/cotton fabrics and other fabrics.

Burn-out fabrics are made of two different fibers, one of which is interwoven or blended. One fiber can be destroyed by a certain chemical agent, while the other fiber is not affected, forming a special style of burnt-out printed fabric. It is usually made of acid-resistant fibers such as silk, nylon, polyester, polypropylene and other fibers and cellulose fibers such as Fabrics made of interwoven or blended fibers such as viscose fiber and cotton are mixed with strong acidic substances for printing. After drying, the cellulose is hydrolyzed and carbonized by strong acid. After washing, a translucent and concave-convex pattern is obtained, which can be used as Decorative fabrics such as curtains, bedspreads, tablecloths, etc. can also be used as clothing materials.

According to relevant information, polyester-cotton core-spun yarn fabrics are mostly used in China, and strong acid slurries are used to print on the fabrics. Sulfuric acid is the preferred strong acid. Acidic salts such as aluminum sulfate and sodium bisulfate can also be used, but the effect is not as good as sulfuric acid.

How to operate burnt-out fabrics

The method is to add acidic chemicals, such as sulfuric acid, aluminum sulfate, aluminum trichloride, etc., into the acid-resistant burnout pulp, and then print, bake or Steaming and high-temperature carbonization corrode the part of cotton or viscose fiber printed with acidic slurry without damaging the silk or polyester, and then wash away the fiber residue of the carbonized part of cotton or viscose fiber. Acid-resistant dyes can also be added to the printing paste, so that while destroying one fiber, another fiber such as silk can be dyed to obtain colored burnout printing.

Notes

The printing paste should be resistant to strong acid, have good permeability, have clear printing outlines, and be easy to wash off. Such pastes include white dextrin, synthetic dragon gum, oil/water emulsified paste, etc. After printing, it is dried, baked at 140°C for 30 seconds, and washed in a rope shape to remove char.

If the baking temperature is too high, the printed area will be dark brown and difficult to clean. When it is not enough, the printed area will appear white and opaque, indicating that the effect is insufficient and it is difficult to wash off. Generally, it is better to choose a light yellowish brown color after baking. Check whether the baking temperature is appropriate and whether the residue on the product is easy to wash away. You can pull the fabric with your hands under tension to make the residue fly away immediately.

Polyester-cotton blended fabrics can be printed with aluminum sulfate or sulfuric acid, with a sulfuric acid concentration of 98 % sulfuric acid 30~33mL/kg, steam for 3 minutes at 95~97℃ after printing. The residue is easy to remove during rope washing, but the temperature must be strictly controlled to prevent the printing paste from bleeding and causing blurred patterns.

Adding disperse dyes to burnout slurry can be used as a colorant for polyester to obtain Tinted burnout print. However, disperse dyes must be S-type or SE-type varieties that have good acid resistance and do not agglomerate when exposed to acid. Acid-resistant paint can also be added to the physalis for coloring.

Burn-out printing equipment can use a roller printing machine, but the depth of the roller engraving should be relatively normal The roller is deep, the printed pattern with a depth of 140-160μm has a smooth outline, and the transparency with a depth of 170-190μm is good. Flat screen printing equipment can also be used, but the efficiency is low and the cost is high. Some fine patterns such as colored moiré, fine dots and airbrushes are difficult to produce.

The burnout printing method can be direct printing or resist printing, that is, printing with slurry in advance, drying and then pickling, Steaming removes the ground color to achieve special effects.

Burn-out printed products are known for their elegant and novel appearance, soft and smooth feel, drape The elegant and colorful unique style has won praise from consumers.

At present, fiber chemistry is used in various burnout printing processes and products. designed and implemented to vary in performance. Such as polyester-cotton burnout products, viscose/silk burnout products, polyester-viscose burnout products, etc.

Burn-out fabric design generally uses plain weave. The following issues should be paid attention to in fabric weave design:

1. Selection of fabric tightness.

The tightness of burnt-out fabrics includes two concepts. One is the tightness of the core-spun yarn part of the fabric.

2. It is the tightness of the fabric screen part.

If the fabric is too tight, weaving production will be difficult. If the fabric is too tight, the warp and weft yarns will easily shift in the screen part.

3. The choice of burnt-out gray fabrics. The main burnout gray fabrics available on the market are The following types: Polyester or cotton core-spun white cloth, the burnt-out part has good transparency, and is suitable for high-end burnt-out products. Polyester or cotton blended fabrics have poor transparency in burnt-out areas and are suitable for general burnout products.

Designers should pay attention to the following issues when designing sketches: Burnout sketches Appropriate gaps must be left at the pattern wiring, and the lines must be fine, well-proportioned, and accurate. The selection of reed size for weaving is based on the uniform arrangement of warp and weft yarns of burnt-out fabrics. Generally, steel reeds with a higher reed size should be used, as it has a significant effect on improving product quality. In actual production, it is best to wear one warp yarn per reed when reeding, and at most two warp yarns per reed. In addition, the selection of the twist coefficient of the core-spun yarn is also closely related to the quality of the burnout fabric.