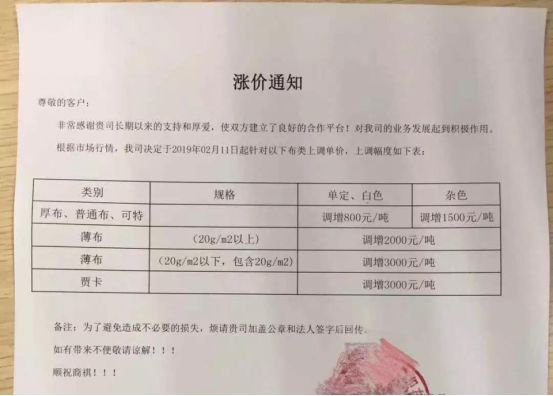

Recently, just when everyone is recruiting for the “labor shortage” after the Spring Festival, the printing and dyeing market in Fujian has launched the “first shot” of price increases in the new year. Many local companies announced on the 13th News of dye fee increase.

After the Spring Festival, The dyeing fees in Fujian area are the first to be announced. What does this mean?

1. Dye prices are running at high levels, and printing and dyeing enterprises are under great pressure

After the market baptism in the second half of last year, the overall price of disperse dyes has stabilized. Compared with the same period last year, the price has not increased significantly. The unit price of some dyes has shown signs of recovery. The ex-factory price of dispersed Dahei ECT has stabilized at 45,000 yuan/ton. , dispersed dark blue HGL200%: 46,000 yuan/ton, dispersed red GS: 40,000 yuan/ton.

Although the price of dyes has not increased significantly, its The price is still at a high level. Compared with the mainstream ex-factory price of 26,000 yuan/ton for dispersed black ECT 300% in 2017, it has increased by 42.2%. This has also put certain pressure on printing and dyeing companies. In order to make profits, printing and dyeing companies also seem to be raising dyeing fees. It makes sense.

2. After the Spring Festival, printing and dyeing enterprises will enter the peak production season, and warp knitted fabrics will develop well

The warp knitting industry in Changle, Fujian and other areas is well developed and is a gathering place for mesh fabrics, mesh fabrics, lace fabrics, lace, and shoe fabrics. After the Spring Festival, printing and dyeing companies will enter the annual peak production season, and the orders they receive will increase. This year, some printing and dyeing companies have unfinished orders before the Spring Festival, causing printing and dyeing companies to have doubts about the success of the warp knitting market in the first half of the year. He has great confidence, so he has the confidence to increase the dyeing fee price.

3. Affected by environmental factors, production capacity has been reduced and dyeing costs have increased

In recent years, environmental protection issues have always been a sharp knife hanging over the heads of enterprises. Printing and dyeing enterprises frequently restrict production, limit production, shut down, and rotate production. The limited production capacity of printing and dyeing enterprises has become the trigger for the increase in dyeing fees in recent years.

In general, production capacity is limited and output declines, but downstream demand is increasingly strong, coupled with high dyeing costs , profits are decreasing day by day, and under pressure, printing and dyeing companies in Fujian have to increase dyeing fees.

The increase in dyeing fees in Fujian has become a fact, so what is the current situation of printing and dyeing factories in Jiangsu and Zhejiang?

According to the editor’s understanding, currently, all companies have not received notice of the increase in dyeing fees in Jiangsu and Zhejiang. This is undoubtedly good news for cloth bosses, but whether the increase in dyeing fees in Fujian will affect Jiangsu and Zhejiang regions, the author will briefly analyze it below:

1. In the early stage of resumption of work, the production situation has not yet stabilized

At present, textile enterprises are just in the early stage of resumption of work, and not all workers have There are positions in place, there are vacancies, and everything is not on track. Although the salesmen have begun to take orders and the blanks have been put into the warehouse, the actual dyeing production has not yet begun. In the face of many unstable factors, printing and dyeing companies do not seem to take the price increase into account, and they do not have much confidence to issue notices of increases in dyeing fees.

2. Different industrial clusters have different dyeing fees

As we all know, Fujian is dominated by the warp knitting industry, and there are large differences in the start-up of printing and dyeing enterprises and textile trade. In recent times, orders for warp knitting products in Fujian have maintained a good momentum, and in There are more printing and dyeing factories for polyester fabrics in Jiangsu and Zhejiang regions. At present, most of the printing and dyeing factories in the region are not in operation, and the textile market does not receive many orders. Therefore, regional textile differentiation cannot lead to a common feature of rising dyeing costs.

3. The price of dyeing fees is already at a high level and it is difficult to follow the trend and rise

Although Fujian has launched the first shot of increasing dyeing fees in 2019, throughout 2018, dyeing fees in Shengze have increased three times, and dyeing fees have always been at a high level. If it rises again, it will inevitably destroy the balanced development of the industrial chain. When the time comes, customers will not buy it, which is a situation that no one wants to see.

Editor’s note: Although there is currently no notice of price adjustment for dyeing fees, if The cost pressure on dyeing factories continues to increase. In the first half of this year, like last year, dyeing factories burst into warehouses and queued up to dye fabrics. It is inevitable that dyeing factories will make price adjustments.

Whether dyeing fees will rise at the same time is not only determined by the costs of printing and dyeing enterprises, but also needs to be combined with the conditions of the entire weaving market. We are currently in the beginning of the new year. The weaving market received orders well at the end of last year, but it will take some time for the short-term operating rate to recover. Therefore, the delivery time pressure is not very big for the printing and dyeing companies in Jiangsu and Zhejiang, and it is not suitable to work here. Prices rise from time to time, so judging from the current situation of the textile market, the increase in dyeing fees in Fujian may be just an example. In the future, we need to pay attention to the orders received in the gray fabric market and the pressure on environmental protection in printing and dyeing.

</p